Create A Cordless Power Tool Ecosystem

In our daily lives, there are a lot of ongoing gardening work and renovation projects, which can be easily completed with the help of cordless power tools. I recently bought an 18-inch cordless chainsaw for household use, and I like it very much. I can cut down trees up to 12 inches in diameter without worrying about it not starting or pulling the starting line-it’s worth buying. My cordless chainsaw is powered by a 40 V/5 Ah lithium ion battery or 200 Wh, which can effectively provide about 200 W for 1 hour. Or, provide about 400 W for about 30 minutes, depending on the motor.

Power tools, especially cordless power tools, came out in 1961, when Black and Decker created the first cordless electric drill, which was mainly sold to industrial and commercial companies. In 1969, Makita released the 6500D, which was the first rechargeable cordless drill sold to the general public.

Today’s power tool suppliers are experiencing explosive growth. As individuals spend more time at home, many people make renovations on their own, while others are hiring contractors to make improvements or upgrades to change the landscape. In addition, the growth of Industry 4.0 has led to recent technological innovations in brushless DC (BLDC) motors and lithium batteries. Power tool buyers benefit from a practical, buyer-friendly, and easy-to-use cordless power tool ecosystem that includes hundreds of tool types and is powered by two to four battery systems.

For example, Table 1 lists a company’s ecosystem of hundreds of power tools. These products are powered by 3 different lithium-ion battery systems; M12, M18 and MX Fuel, which naturally expand to the power required for the corresponding work. No matter what the job or project, this power tool company can provide everything you need, from simple drill bits to jackhammers, construction site lighting, chain saws, nail guns, sanders, heavy saws, rivets and even electric clothing.

01 Industry 4.0

Cordless power tools are also gaining market share in various industries such as auto workers, aerospace, white goods and agricultural equipment manufacturers, and Industry 4.0. This is due to improved mobility, safety, higher torque, higher accuracy and data collection capabilities. The advancement of lithium battery technology reduces cables and tripping hazards, enables workers to move freely in a narrow range and eliminates concerns about accidental cuts in power cables, thereby realizing freedom of movement.

Product quality, reliability, and longevity can be directly attributed to the torque and revolutions per minute (RPM) control indicators that maintain precise calibration during factory manufacturing and assembly. The latest innovation in BLDC motor control achieves very strict control and accuracy of torque and RPM. Some cordless power tools include Wi-Fi or Bluetooth Low Energy (BLE) so that a centralized controller can ensure that all devices are assembled accurately and consistently.

For example, five factory workers can install fasteners on five assembly lines in three different shifts. The wireless connection enables 24/7 user-certified RPM/torque control accuracy and repeatability on all 5 assembly lines, not to mention automatic real-time data logging to meet quality manufacturing compliance indicators and historical program tracking.

02

Mobility

The mobility of power tools has many meanings. The tractor driver has a cordless lithium ion drill in the engine room for use in case of malfunction, which is of great benefit to them. Agricultural workers can carry out small equipment repairs without having to return to their barns. Wind and solar installation technicians benefit because it is impractical to run power cables longer than 100 feet.

The same is true for residential/commercial equipment such as oil/gas stoves, heating, ventilation and air conditioning (HVAC), electrical updates and inspections of plumbing systems, preventive maintenance and on-site repair services.

Moreover, for new construction sites, when there is no main power supply, the traditional generator power supply may bring stress to the motor of the wired power tool due to the fluctuation of the power supply on the line, especially when many power tools are working in parallel. . Or, if the fuel of the generator is accidentally depleted during use, the motor will be damaged. Many new construction sites now use generators to charge multiple batteries to buffer the power tool motors from fluctuations in AC power.

The lithium-ion battery provides a very clean DC voltage to the motor, which maximizes the service life of the motor. Wherever it is difficult for workers to access, cordless tools can help.

03

Lithium-ion battery

Most cordless power tools use 18650-shaped cylindrical lithium-ion batteries. 18 means that the diameter is 18 mm, and 650 means that the length is 65.0 mm.

The rated voltage of the 18650 ranges from 3.3 V to 3.7 V, depending on its cathode chemical composition. Sometimes called a “jelly roll battery” (the internal anode, cathode, separator and electrolyte are rolled on a central axis), 18650 can be connected in series to increase voltage, or in parallel to increase capacity, or both Of. For example, five 3.6 V (nominal) 3 Ah batteries connected in series = 18 V (5 x 3.6 V), or 54 Wh (3 Ah x 18 V).

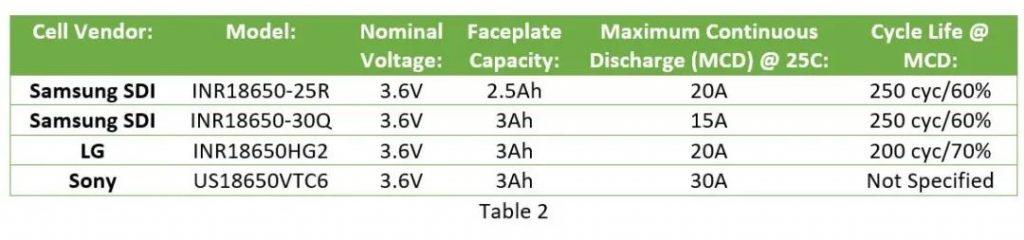

Cordless power tool suppliers work closely with Li-ion battery suppliers to optimize “Maximum Continuous Discharge” (MCD) performance and cost, weight, charge rate, cycle life, capacity, and durability (shock, vibration, and temperature tolerance) Relationship. Table 2 lists several examples of 18650 lithium-ion batteries used in cordless power tools today.

04Brushless DC Motor (BLDC)

BLDC motors have many advantages over brushed permanent magnet DC (PMDC) motors, especially higher reliability, almost no maintenance, lower electrical and acoustic noise, better thermal performance, higher speed range and Power density.

A typical cordless power tool BLDC motor uses permanent magnets on the rotor and three armature windings (U, V, W) on the stator. The microcontroller (MCU) implements one of a variety of control and modulation schemes (trapezoid, sine, FOC with SVM, DTC, etc.) to strategically power the motor windings. This generates an electromagnetic field, which creates an interaction force between the rotor magnet and the stator winding. If handled properly, this interaction can precisely control the speed, torque, or power of the motor in the desired direction.

Figure 1 shows a typical block diagram of a cordless power tool based on a 3-phase BLDC motor. The MCU executes the control and modulation scheme firmware, which instructs its PWM peripheral to output six coordinated duty cycles to the three NCP81080 (2 mm x 2 mm) half-bridge gate drivers. These three drivers act as the power steering for the six power MOSFETs in the output bridge, supplying power to the U, V, and W MOSFETs of the lower bridge (LS) and upper bridge (HS).

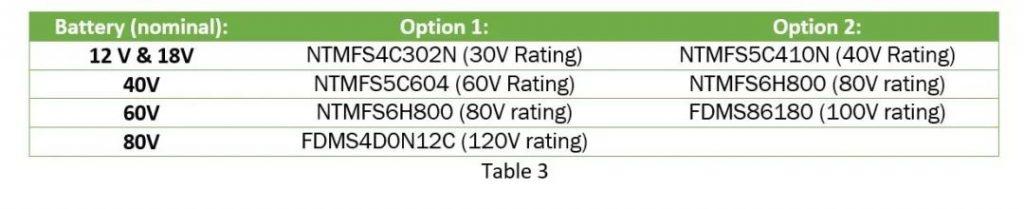

These are usually N-channel MOSFETs with a rated voltage of 1.5 to 2.0 times the battery voltage, as shown in Table 3. The drain-to-source (VDSS) voltage is a first-order approximation parameter for selecting MOSFETs. There are many other considerations when choosing a MOSFET, including BLDC power, as well as cost, RDS(on), QG, packaging, etc.

MCU can measure the current through each winding through NCS2007x (typical bandwidth of 3MHz), and can choose to use Hall effect sensor feedback to evaluate the angular position of the rotor. In addition, a sensorless architecture can also be implemented, but with more processing overhead. RSL10 BLE can be used for battery/tool asset tracking, firmware over-the-air update (FOTA), function selection/adjustment and telemetry data collection.