What Are The Woodworking Power Tools

With the continuous development of science and technology, woodworking tools have also developed from purely manual to electric tools, and many traditional hand-operated woodworking tools have been gradually replaced by electric tools. So, what are the woodworking power tools? how to use?

There are many categories of basic woodworking tools, and there are many subcategories under the category. Only the commonly used basic tools are introduced here.

- Planer

Table planer is usually the basis of traditional woodworking, and it is the most basic power tool. The work of the table planer can be replaced with a hand saw and a hand plane after the line is made with the ink fountain. The rotating speed of the table planer is usually low, and the planed surface will have large ripples, so it cannot be used directly.

- Press planer

Press planer is a common woodworking tool. In order to ensure a relatively uniform planed surface, it is usually automatically fed at a constant speed, generally 6-8 meters per minute. The speed of the pressing planer is usually higher, and the planed surface is much smoother and more flat than the table planer. Since the wood is placed between the blade and the base plate, batches of wood can be processed with good final specification consistency. It belongs to the efficiency equipment, and the manual plane can also be used to replace this function.

- Table saw (flip-chip chainsaw)

Table saw is one of the most basic tools for woodworking. Now the finished table saw generally has functions such as lifting and tilting, and has accessories such as backing and pushing plates. The basic purpose of the table saw is to cut the material with the backing (foot), that is, to cut the wood into the section size we need. From an economic point of view, many people will use ordinary hand saws to be flipped and converted into table saws. If they also want to have the basic functions of ordinary finished table saws, they need to choose a hand saw that can be lifted and tilted for modification. Table saws can be used for tenoning, grooving and many other purposes with suitable accessories and saw blades.

- Handheld circular saw

Hand-held circular saws are ordinary chainsaws. They are generally used on materials that are larger in size and cannot be used on table saws. They are mostly used to open large finger-joint boards, and to cut long and thick wooden squares. Many hand-held circular saws are now adjustable for height and tilt. There are also more rechargeable circular saws on the market, which use DC power and are more convenient to use.

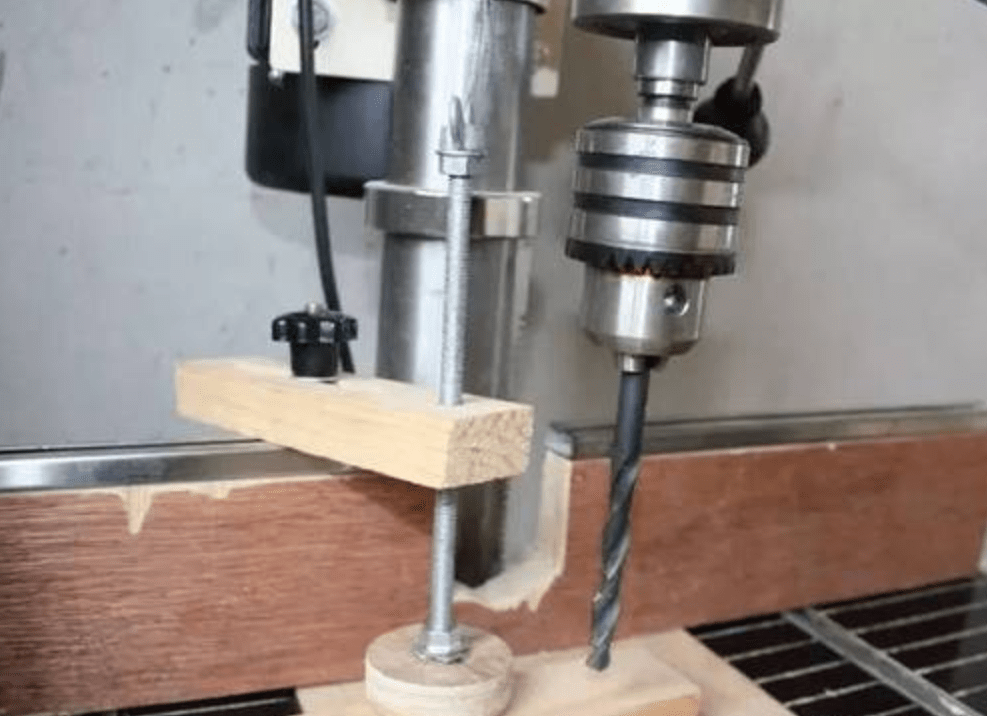

- Bench drill

The size and power of the bench drill are quite different. Generally, it is used for vertical drilling, digging holes, etc. Due to the large weight and the bottom plate, it is convenient to set the depth, replace the drill bit, and cooperate with the template to do a lot of work. Drills, hole saws, aircraft hole saws, etc. are used as accessories. Generally, the power of the bench drill is large, and the speed and torque are adjustable.

- Hand drill

The electric hand drill is the basic woodworking tool, and it is also one of the most common and widely used electric tools. Due to the small size of the hand drill, it is very flexible compared to the bench drill, so it is widely used. There are two categories of electric hand drills: charging and plugging, which are further divided into ordinary drills, impact drills, electric hammers, and electric picks. The impact drill has an impact function, which can hit cement walls and ceramic tiles. It is relatively accurate, but the power is generally not large. It is limited to punching finer installation holes. Generally, the electric hammer has high power for penetrating walls, punching large holes, etc., and is generally used for decoration. . Electric picks are generally very powerful and are mostly used in engineering.

- Electric screwdriver

A simple understanding of an electric screwdriver is a tool used to replace a screwdriver. Since woodworkers often use various self-tapping screws, it is very difficult to use longer and more screwdrivers on a manual screwdriver, and an electric screwdriver is very practical to use. Electric screwdrivers are usually charging tools, ranging from 6V to 24V, mostly 7.2V-18V batteries, and mostly industrial-grade plug-in tools. The principle of the electric screwdriver is basically the same as that of the electric drill, but the rotation speed is low, the torque is large, and most of them have torque adjustment, which can be used with various screwdriver heads to adapt to different types of self-tapping. Some electric screwdrivers also have the function of electric drill.

- Engraving machine (bakelite milling)

The engraving machine is a tool used by both professional manufacturers and enthusiasts. The woodworking engraving machine is also called a bakelite milling machine. It is not an index-controlled engraving machine. Large-scale bakelite milling machines have large diameters and are not introduced. The engraving machine can be used with various blades to complete various functions such as slotting, trimming, digging, tenoning, and color. There are about dozens of commonly used cutter heads, and hundreds of common ones. The engraving machine can cooperate with the template to do various carvings, lettering, graphics, special shapes, etc. The engraving machine originated in Europe and the United States. The caliber of the blade is generally British, with a 2/1 aperture, which is about 12.7 mm. There are usually two categories of engraving machines: adjustment type and compression spring type. Adjustable engraving machines are mostly used for flipping, and the 890 of Bupai is typical. Compression spring engraving machines are mostly hand-held, typically DeWalt 618.

- Trimming machine

A simple understanding of the trimming machine is a small bakelite milling machine, which is small in size and low in power. There are also many types of blades, but they are generally smaller. Because of its lightness, it is very convenient to operate with one hand, and it is mostly used for trimming, so it is called a trimming machine. The function is basically the same as that of the engraving machine, but the working depth and width are limited to the power and cannot be too large.

- Electric circular grinding (square grinding)

Electric circular grinding refers to a kind of electric equipment with brushed bottom plate, which can quickly replace brushed sandpaper. Generally, it is small in size, flexible and convenient to operate, and can be operated with one hand. The rotating speed of the electric circular grinder is relatively high, and it generally rotates eccentrically. It can be used to treat the surface of various boards and wood. By changing the brushed sandpaper with different meshes, the surface of most wood can be treated. The square grinding base plate is square or rectangular, and the wood surface is processed by the principle of front and rear high-speed vibration.

In addition to the above woodworking power tools, woodworking power tools also include biscuit tenoning machine, desktop engraving machine (flip), jig saw, air pump (nail and paint), nail gun, desktop abrasive belt (drum) machine, angle grinder, hand-held Electric planer, desktop engraving (pulling) saw, band saw, etc.

YKTECTOOLS is an prefessional tools supplier for years,If you have any requirements to purchase or OEM the power tools,just contact us by support@yktectools.com

Amazing blog! I love to read your blogs.